Innovative solutions for your challenging requirements

We have what it takes

When our standard equipment solutions don’t meet your design, our Engineering Team can adapt or create a system to fit your requirements.

We specialize in factory, depot, or military equipment testing environments. We know that constraints are many…limited space, safety and regulatory factors, unique control requirements, power monitoring, or even color coordination, and the list goes on…

Explore some of the ways AC General can adapt an equipment rack power system for you…look over the gallery below for examples

Customization Examples

Input And Output Power Connectors

-

- High Durability NEMA connectors are standard but optional MIL connectors are available

- Different Power input/output connectors can be specified to suit the application

- Custom power cord lengths available

Service Ratings

-

- Typical Service ratings

- Typical voltage ratings: 120, 120/208, 208, and 480 VAC

- Typical current ratings: 5- 60A

- 60 Hz and 400 Hz

- Typical Service ratings

Control

-

- Any Power Distribution Panel can be equipped with Remote Control

- Using a variety of control switches, AC General can provide almost any power control scheme needed

- Other remote control features can be added such as:

- Digital interface to a Computer/PC/VXI system (typically 5VDC or 24VDC digital IO signal levels)

- Other enable signals from door, fan, or other sensor switches

- E-Stop (from single or multiple locations)

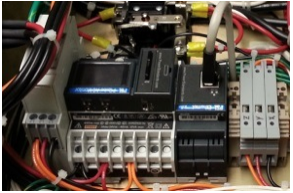

- If more advanced control logic is required we employ Programmable Logic Controllers (PLCs)

Packaging And Protection Options

-

- Custom panel sizes or shapes

- Unique panel colors can be provided on our panels to match your system color

- Breaker guards

- Ruggedization

- Special EMI and AC Filtering considerations

System Monitoring

Other options to consider when specifying your equipment rack power distribution system:

-

- Over/Under voltage and Phase Rotation monitoring

- This option removes output power if any of the above conditions are detected

- Elapsed time meter for tracking operational time

- Current monitoring

- Read current on a front panel meter or have the data available to your host PC

- Power quality monitoring

- A more sophisticated means of monitoring and logging system power quality

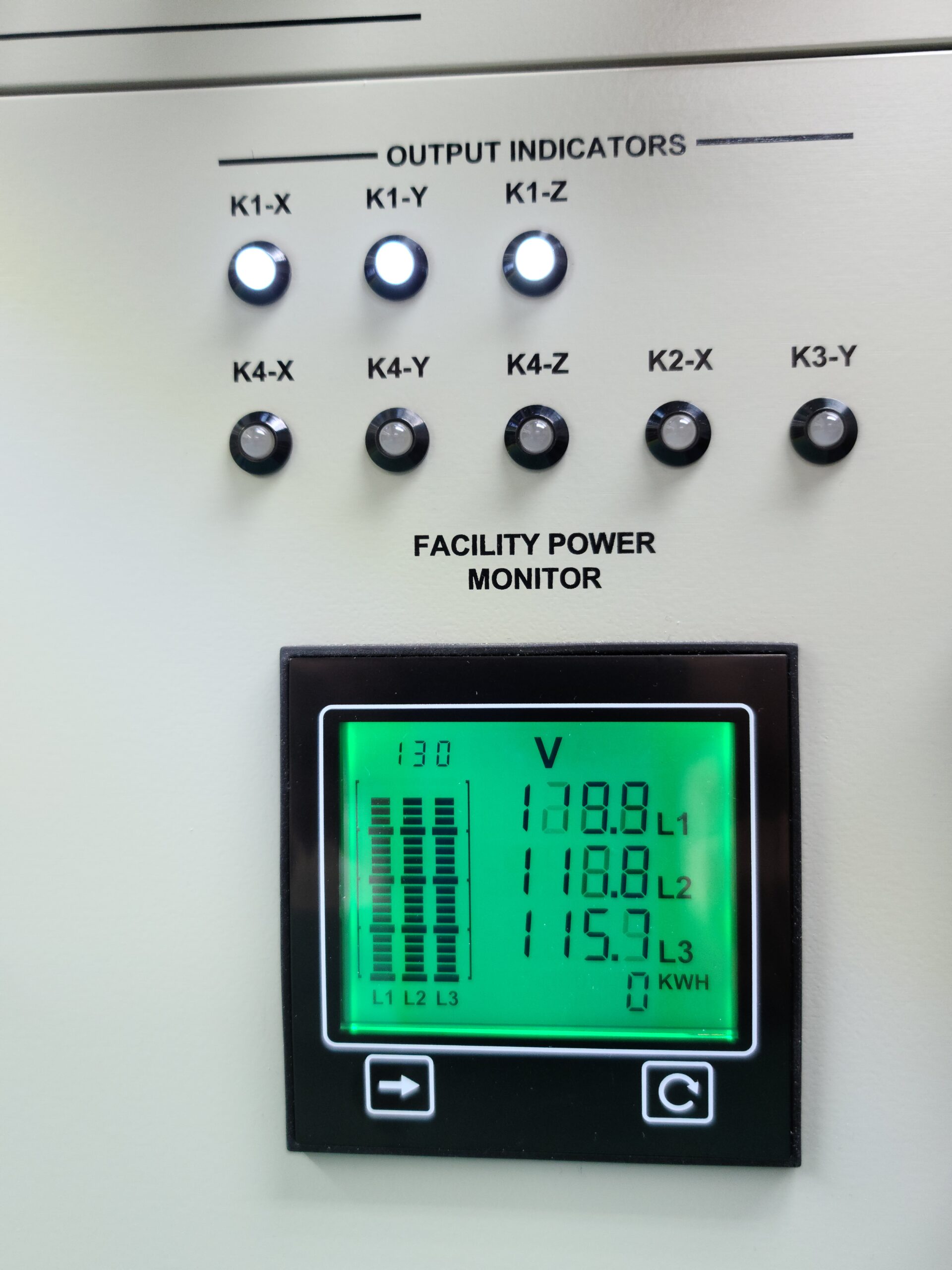

- Metering

- Add a front panel meter for displaying voltage, current, and power parameters

- Networking to host computer

- Modbus protocol

- Over/Under voltage and Phase Rotation monitoring

Need More Information?

Interested in learning more about this product or how AC General can custom engineer a product specifically to fit your needs?

The easiest way to reach us is through our online contact form.

Control Options

Get On/Off power control switches

integrated on the PDU front panel

Get all the switching that you need located

on one control panel

Line-rated main selector switch

Compact specialized control (1U) panels

Various ON/OFF control and Emergency Off (EMO) schemes available

Get multi-PDU system control from a single control panel

Packaging & Protection

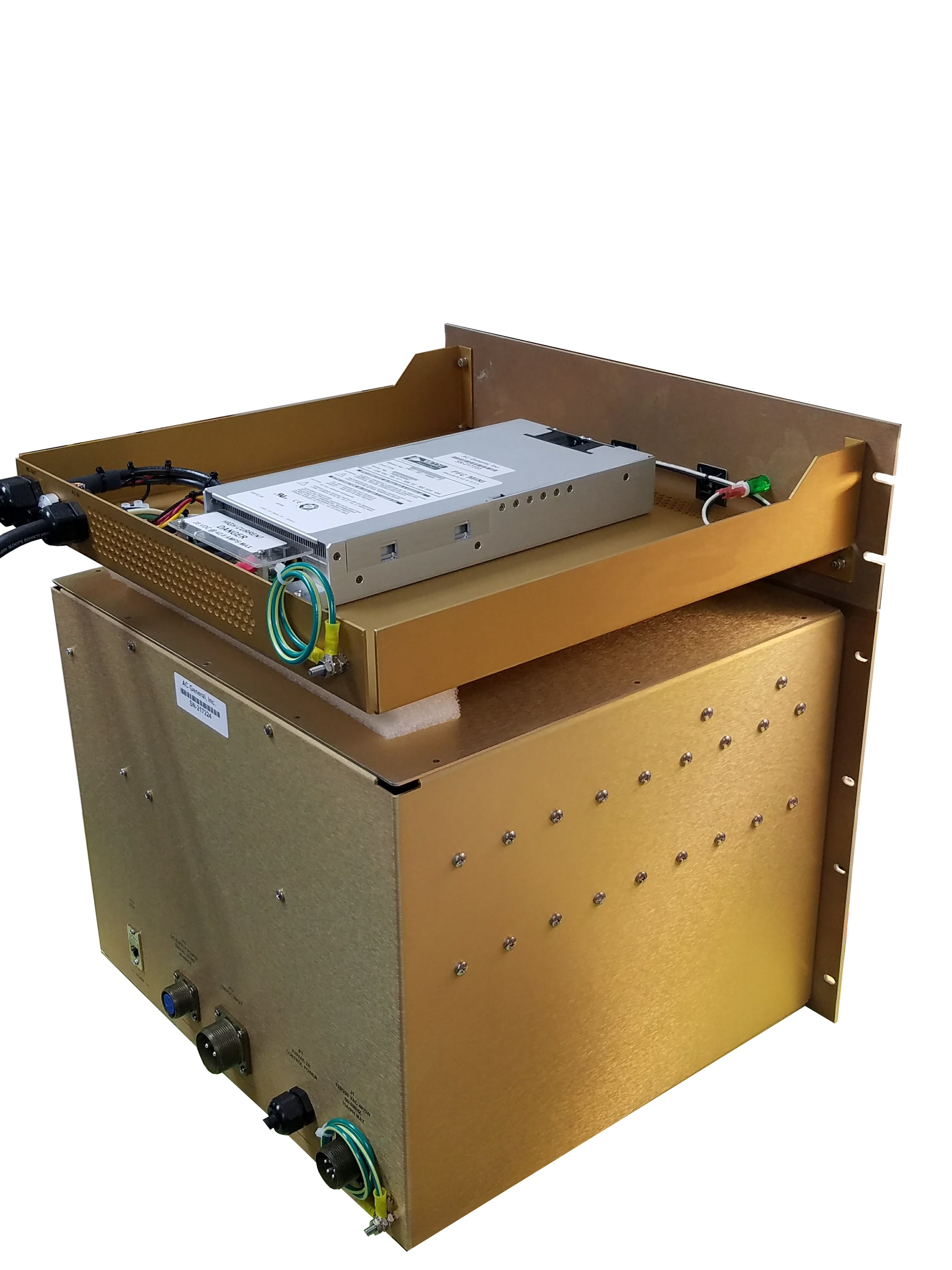

Unique packaging designed to manage tight rear panel cabling

Custom panel design for highlighting 8U distribution panel (bottom) +

accompanying 3U DC distribution panel (top)

Various forms of guards for 1/2/3/4-pole circuit breakers

System Monitoring

Over/Under Voltage and Phase Rotation

- Prevents damage to equipment by disengaging the PDU outputs

- Enforces phase sequence wiring to A-B-C

Current Monitoring

- Monitor AC Line Current with added current sensing

- Feed the sensor to built-in meters or route the sensor wiring to your measurement equipment

Power Quality Monitoring (PQM)

- Embed a PQM into your PDU and get

- Detailed event recording for voltage, frequency, and current

- Voltage dips, swells, and interruptions

- Waveform graph and RMS graphs

- Network connectivity to retrieve all the AC PQM data into your host system

- No software required!

- Built-in web server

- Built-in FTP server

- Built-in Modbus-TCP protocol

- Perfect option for critical test environments where you need to correlate AC power events to test results

- No more guess-work on power sags and surges

- Easy to configure

Panel Meters

- AC General has incorporated numerous meters into our distribution panels to display

- AC (and DC) voltage

- AC (and DC) current

- Line frequency

- Power

- Meter data can be optionally sent back to a host PC via Modbus